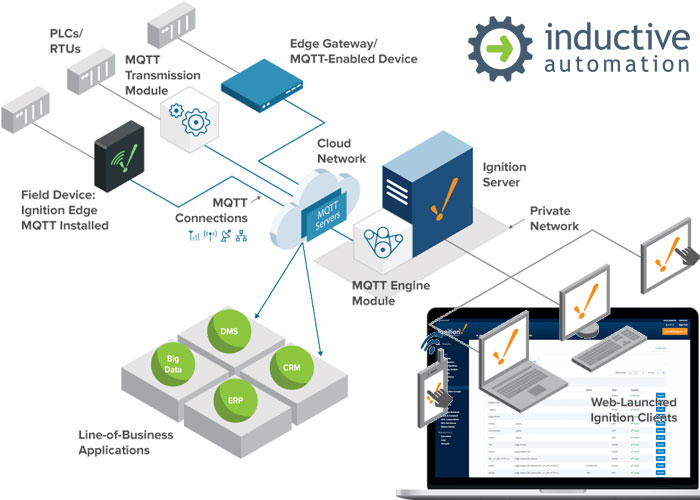

- Your Personal System Integration Platform. Ignition Maker Edition TM is cross-platform server software that's agile enough to run on your own computer. Ignition uses trusted technologies like SQL, Python.

- Wrong Key, Wrong Car. The average car key only has a few hundred thousand combinations.

- Ignition is made by Inductive Automation, based in Folsom, California. Inductive Automation was founded in 2003 by Steve Hechtman, a systems integrator with over 25 years of experience who grew frustrated.

Ignition definition, the act or fact of igniting; state of being ignited.

By The Gas Engine Magazine Staff | Sep 10, 2020

Frank Tremper's Original igniter patent incorporated a spring-loaded contact (item 'G' in Fig. 2) set in the piston head. Included in the patent was his scheme for a chain-driven rotary valve to control intake and exhaust (item 'P' in Fig 1.)

Most antique engine collectors are familiar with 'make-and-break' ignition systems. In this ignition style, two contacts come together, and a spark is created when they separate. One contact carries a low-voltage current, and the other goes to ground. An inductive coil in series with the contacts builds voltage during the brief time the points are closed, producing a voltage 'kick' when the points open.

Make Ignition Circuit

Numerous manufacturers used this rudimentary ignition scheme, but Frank E. Tremper, San Francisco, California, designed one of the earliest systems. In 1891 Tremper submitted a patent application on behalf of the Safety Vapor Engine Co., New York, New York, for 'An Improvement in Explosive Engines.' The final patent, no. 495,281, which also included Tremper's design for a rotary valve, was issued April 11, 1893.

Ignition

The key feature of Tremper's igniter was a spring-loaded contact, or 'rod,' set into the crown of the piston. A pair of stationary electrodes were set into the combustion chamber, and when the piston reached the top of its travel the rod made contact with two stationary electrodes (which could be configured any number of ways), completing the ignition circuit. The rod was tapered at its contact end to encourage a self-cleaning scraping action between the rod and the electrodes.

By containing the spring-loaded contact in its own fitting in the crown of the piston, the damaging effects of heat on the rod's spring could be minimized. Additionally, Tremper's design meant there were no moving pieces outside the combustion chamber. Curiously, this design was quickly followed by another patent, but it ran along a slightly different line of thought.

Know of an interesting patent? Contact Gas Engine Magazine at 1503 SW 42nd St., Topeka, KS 66609-1265 or email us.

RELATED ARTICLES

Make Ignition Switch

- Your Personal System Integration Platform. Ignition Maker Edition TM is cross-platform server software that's agile enough to run on your own computer. Ignition uses trusted technologies like SQL, Python.

- Wrong Key, Wrong Car. The average car key only has a few hundred thousand combinations.

- Ignition is made by Inductive Automation, based in Folsom, California. Inductive Automation was founded in 2003 by Steve Hechtman, a systems integrator with over 25 years of experience who grew frustrated.

Ignition definition, the act or fact of igniting; state of being ignited.

By The Gas Engine Magazine Staff | Sep 10, 2020

Frank Tremper's Original igniter patent incorporated a spring-loaded contact (item 'G' in Fig. 2) set in the piston head. Included in the patent was his scheme for a chain-driven rotary valve to control intake and exhaust (item 'P' in Fig 1.)

Most antique engine collectors are familiar with 'make-and-break' ignition systems. In this ignition style, two contacts come together, and a spark is created when they separate. One contact carries a low-voltage current, and the other goes to ground. An inductive coil in series with the contacts builds voltage during the brief time the points are closed, producing a voltage 'kick' when the points open.

Make Ignition Circuit

Numerous manufacturers used this rudimentary ignition scheme, but Frank E. Tremper, San Francisco, California, designed one of the earliest systems. In 1891 Tremper submitted a patent application on behalf of the Safety Vapor Engine Co., New York, New York, for 'An Improvement in Explosive Engines.' The final patent, no. 495,281, which also included Tremper's design for a rotary valve, was issued April 11, 1893.

Ignition

The key feature of Tremper's igniter was a spring-loaded contact, or 'rod,' set into the crown of the piston. A pair of stationary electrodes were set into the combustion chamber, and when the piston reached the top of its travel the rod made contact with two stationary electrodes (which could be configured any number of ways), completing the ignition circuit. The rod was tapered at its contact end to encourage a self-cleaning scraping action between the rod and the electrodes.

By containing the spring-loaded contact in its own fitting in the crown of the piston, the damaging effects of heat on the rod's spring could be minimized. Additionally, Tremper's design meant there were no moving pieces outside the combustion chamber. Curiously, this design was quickly followed by another patent, but it ran along a slightly different line of thought.

Know of an interesting patent? Contact Gas Engine Magazine at 1503 SW 42nd St., Topeka, KS 66609-1265 or email us.

RELATED ARTICLES

Make Ignition Switch

Make Ignition Coil Fire

Randy Reysen shares the rescue story of a 12 HP Domestic from the Bahamian jungle.